WATCH MD Mike Schwarz discuss the latest metallurgical results from the Campoona Graphite Project.

HIGHLIGHTS

• Bulk sample metallurgical tests have achieved high purity fine flake graphite suitable for purified spherical graphite (PSG) production

o Number of processing steps has been reduced from 11, in laboratory scale processing, to 8, in bulk sample production, suggesting more cost-effective processing is achievable

o Average purity of ~ 94% total graphitic carbon (TGC) with estimated recoveries of ~80%

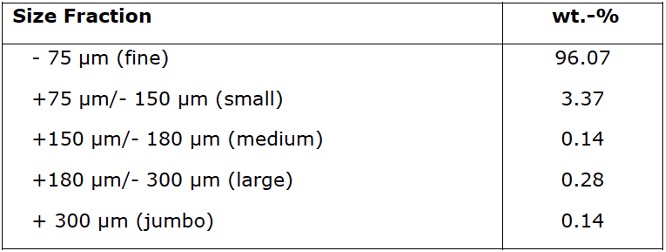

o >99% of graphite flakes are less than 150μm (small flake size) which is used for PSG production

• 42kg of final concentrate was produced from 407kg of processed material

• Results were achieved through conventional graphite flotation process (non-chemical, non-thermal)

• Purification and spheroidization test work is now underway

• iTech has commissioned a detailed scoping (pre-feasibility study) on a vertically integrated PSG project – results expected towards the end of 2022

"With successful bulk sample tests complete, the company is progressing to the final purification and spheronisation test work. This will pave the way for a scoping study on a vertically integrated PSG operation at the Campoona PSG Project."

— Managing Director Mike Schwarz

DETAILS

iTech Minerals (ASX: ITM) has advanced the Campoona Spherical Graphite Project with the production of a 42kg bulk sample of >94% TGC concentrate and recoveries of ~80% using an industry standard flotation circuit.

iTech continues to build its portfolio of critical minerals projects with the production of a 42kg high- quality graphite concentrate from a bulk sample (407kg) of run-of-mine (ROM) graphite ore, processed by ANZAPLAN in Germany. ANZAPLAN has completed the third stage of metallurgical test work to produce purified spherical graphite for use in the anodes of Lithium-Ion (Li-ion) batteries using a low- cost, eco-friendly processing route with a smaller environmental footprint. This collaboration is building on test work completed by Archer Materials between 2015-2019, where Archer successfully produced battery-grade graphite using a traditional hydrofluoric-acid (HF) process.

The Campoona Graphite Project contains a JORC 2012 graphite Mineral Resource of 8.55 Mt @ 9.0% Total Graphitic Carbon (TGC), a granted mining lease and approved multipurpose licences for processing infrastructure and groundwater extraction. iTech is currently investigating the best pathway to produce “green graphite”, including the use of abundant renewable energy available in South Australia.

Metallurgical Results

The third stage of metallurgical test work, to produce a bulk sample of graphite concentrate, has been successful with the production of 42kg of high-quality >94% flake graphite concentrate, from Campoona, with an estimated recovery of ~80%.

Compared to the process developed with smaller lab equipment, the process followed for bulk material production uses less processing steps at a similar final grade. This means that the upgrading factors of the individual stages were higher due to improved selectivity when using the larger flotation cell.

In the bulk sample production, three regrinding stages with a total of five flotation stages (rougher/ scavenger and four cleaner stages, total of 8) were sufficient to produce a product within the given specifications. In comparison, four regrinds combined with a total of seven flotation stages were needed to produce a flotation concentrate with the desired quality, using lab equipment (total of 11).

Test work was undertaken on bulk sample (407kg) of run-of-mine (ROM) graphite ore collected from reverse circulation and diamond drilling at the Campoona Central Deposit. The drill holes were located within areas representative of low strip ratio mineralisation of prime economic interest.

Table 1 shows the flake size distribution that was achieved while focussing on a concentrate suitable to produce purified spherical graphite (PSG). Spheroidization of graphite flakes typically uses the small to fine flakes which means >99% of the sample is suitable for PSG production, enhancing the potential for low-cost processing costs. Concentrates with distributions through the larger flake sizes require additional processing steps, adding to total cost of production.

iTech believes that Campoona has the potential to produce a high-quality and cost-competitive flake graphite concentrate suitable to produce PSG for use in the lithium-ion battery sector.

The Company is confident that on-going optimisation test-work will continue to improve concentrate grade and recoveries.

Next Steps

The first three stages of a 7-stage test work program are now complete.

Review of historical test work data – completed

Development of a beneficiation process (flake graphite) – completed

Flake graphite sample production (50 kg) – completed

Screening of alternative (non-HF) chemical purification routes – underway

Optimisation of chemical purification

Spherical graphite sample production (2 kg)

Confirmation of purification of spherical graphite

Screening of alternative (non-HF) is now underway. Once complete, the optimisation and spherical graphite sample production stages will commence. Results are expected in late August 2022.

Campoona Spherical Graphite Scoping Study

iTech Minerals has commissioned M. Plan International Ltd (M.Plan) to undertake a scoping study on the Campoona Spherical Graphite Project with results expected towards the end of 2022.

In 2016 Archer completed a Scoping Study, including a Mineral Resource Estimate, on the Project. The Scoping Study was followed by various test work campaigns which produced battery-grade graphite using a traditional hydrofluoric-acid flowsheet. During 2021 iTech engaged ANZAPLAN GmbH in Germany (ANZAPLAN) to perform test work to produce spherical purified graphite for use in lithium-ion (Li-ion) anodes. The ANZAPLAN test work focus is on a low-cost, eco-friendly, flowsheet with a smaller environmental footprint. Considering the material changes, iTech will perform a Scoping Study to update the Mineral Resources of the Project, based on current graphite prices, the ANZAPLAN optimised flowsheet, as well as the Scoping Study cost estimates and revised mine production schedule.

The Scoping Study will determine CAPEX and OPEX estimates of the mine, process plant (concentration, spheroidization, purification), and bulk infrastructure and tailings storage facility.

M.Plan is a joint venture between Micon International Limited and ANZAPLAN with a focus on specialty minerals, including battery metals and minerals M.Plan’s integrated suite of consulting services and detailed knowledge of product specifications and markets provides a comprehensive understanding of project dynamics, allowing for the optimization of exploration, resource development, mineral beneficiation, chemical processing, process development and project economics, allowing critical time savings and encouraging innovation.

Resource Expansion Program

The Campoona Graphite Project contains a JORC 2012 graphite Mineral Resource of 8.55 Mt @ 9.0%. iTech could significantly expand its global graphite resources at the Lacroma Graphite Prospect which occurs approximately 30 km to the north of Campoona on EL6643. iTech Minerals owns 100% of the graphite rights on EL6643.

Lacroma corresponds to a prominent Electro-Magnetic (EM) signature that has a potential strike extent of over 12 kilometres. Initial drilling at Lacroma recorded very wide intercepts of graphite (60m @ 6.8% TGC)1. Lacroma graphite, like the graphite at Campoona Shaft and Central Campoona, is high crystalline fine flake graphite. Metallurgical test work undertaken by Archer Materials (ASX: AXE or Archer) in 2015 showed that a 98.6% TGC concentrate using the same conventional flotation and leaching conditions as for the Campoona Deposits1. This suggests that the same processing circuit planned by iTech could also use graphite ore from Lacroma.

iTech is currently planning a substantial drilling program to test the full 12 km extent of the Lacroma EM anomaly. Further drilling at Lacroma has the potential to support a substantial Mineral Resource upgrade.