EYRE PENINSULA

KAOLIN-REE PROJECT

WATCH MD Mike Schwarz’s update while in the field during the drilling program at the Eyre Peninsula Project (2022)

+ Contents

OVERVIEW

PROJECT SNAPSHOT

NAME: Eyre Peninsula Kaolin

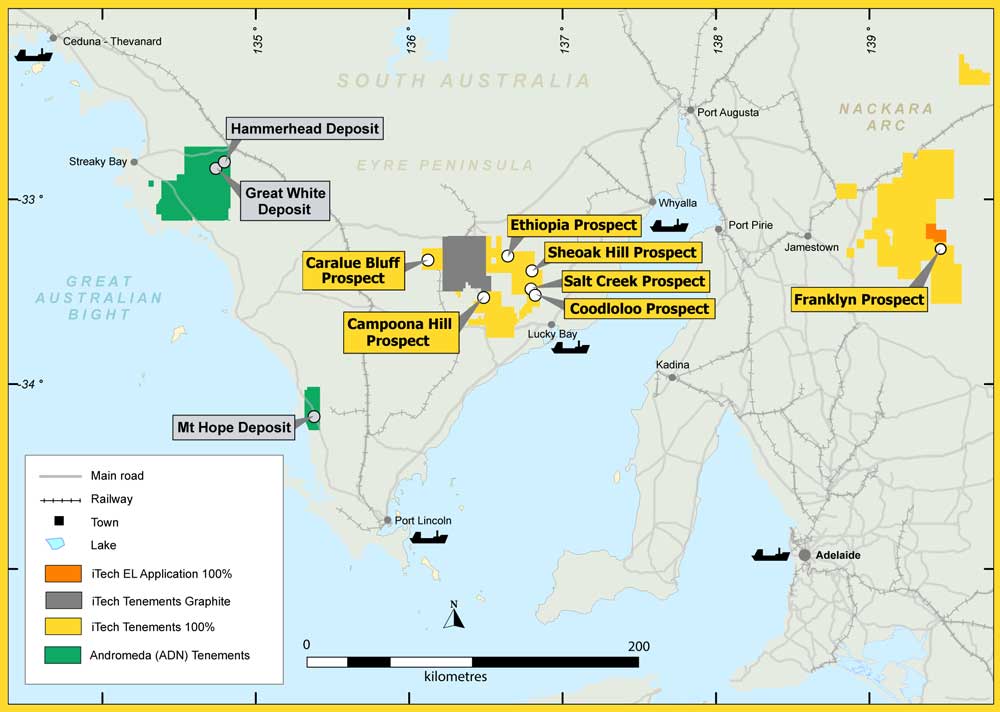

LOCATION: Eyre Peninsula, South Australia

STAGE: Project Development

SIZE: 1445 sq km

TARGET: Halloysite | Kaolinite | Rare Earths

The Eyre Peninsula Kaolin Project occurs over 1,445 square kilometres and has four key prospects prospective for halloysite-kaolinite and rare earth elements (REE). The project area is just 30km from shipping facilities at Lucky Bay and 70 kilometres from the industrial mining city of Whyalla in South Australia.

+ Click to enlarge

EXPLORATION

• THE CARALUE BLUFF PROSPECT

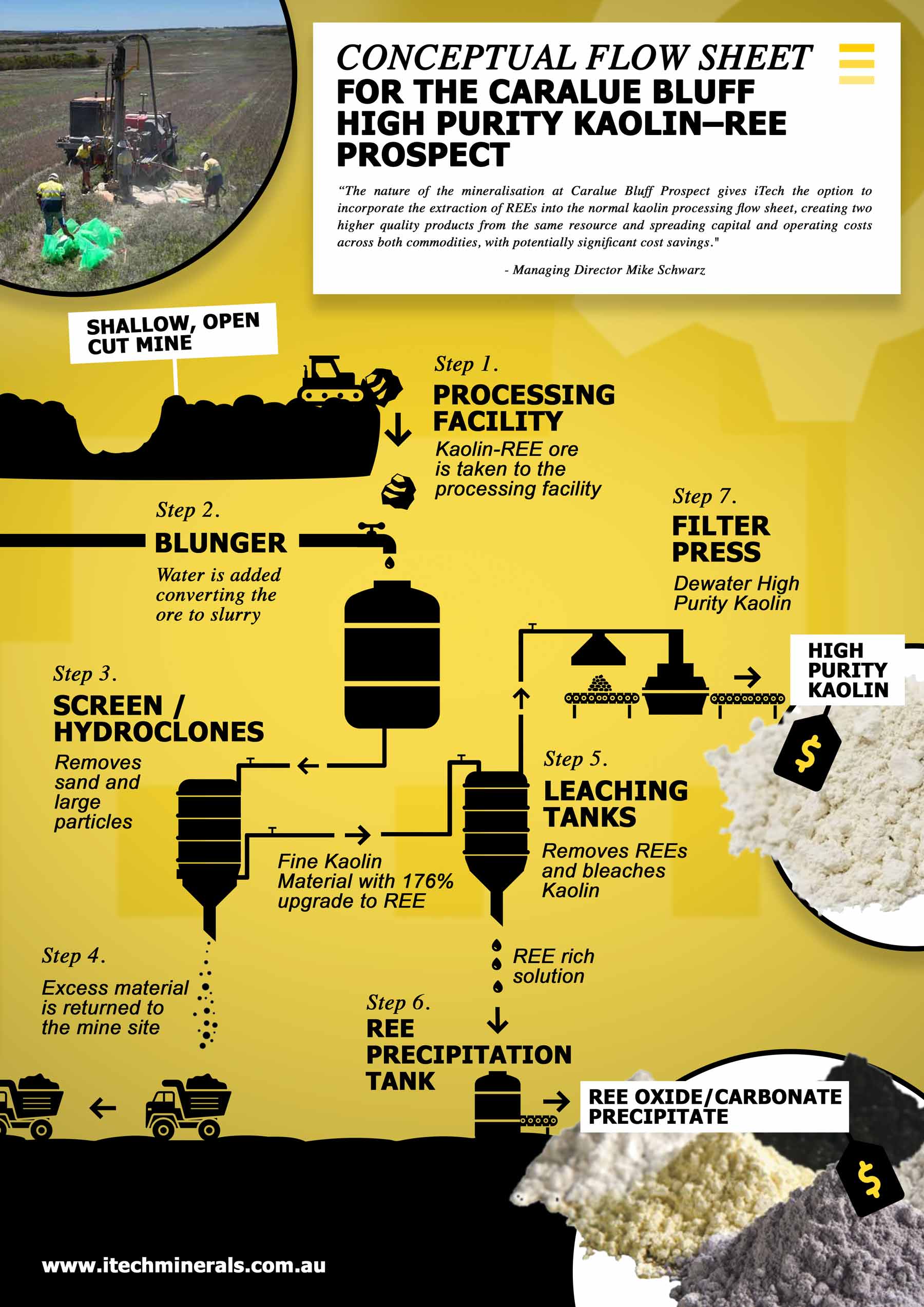

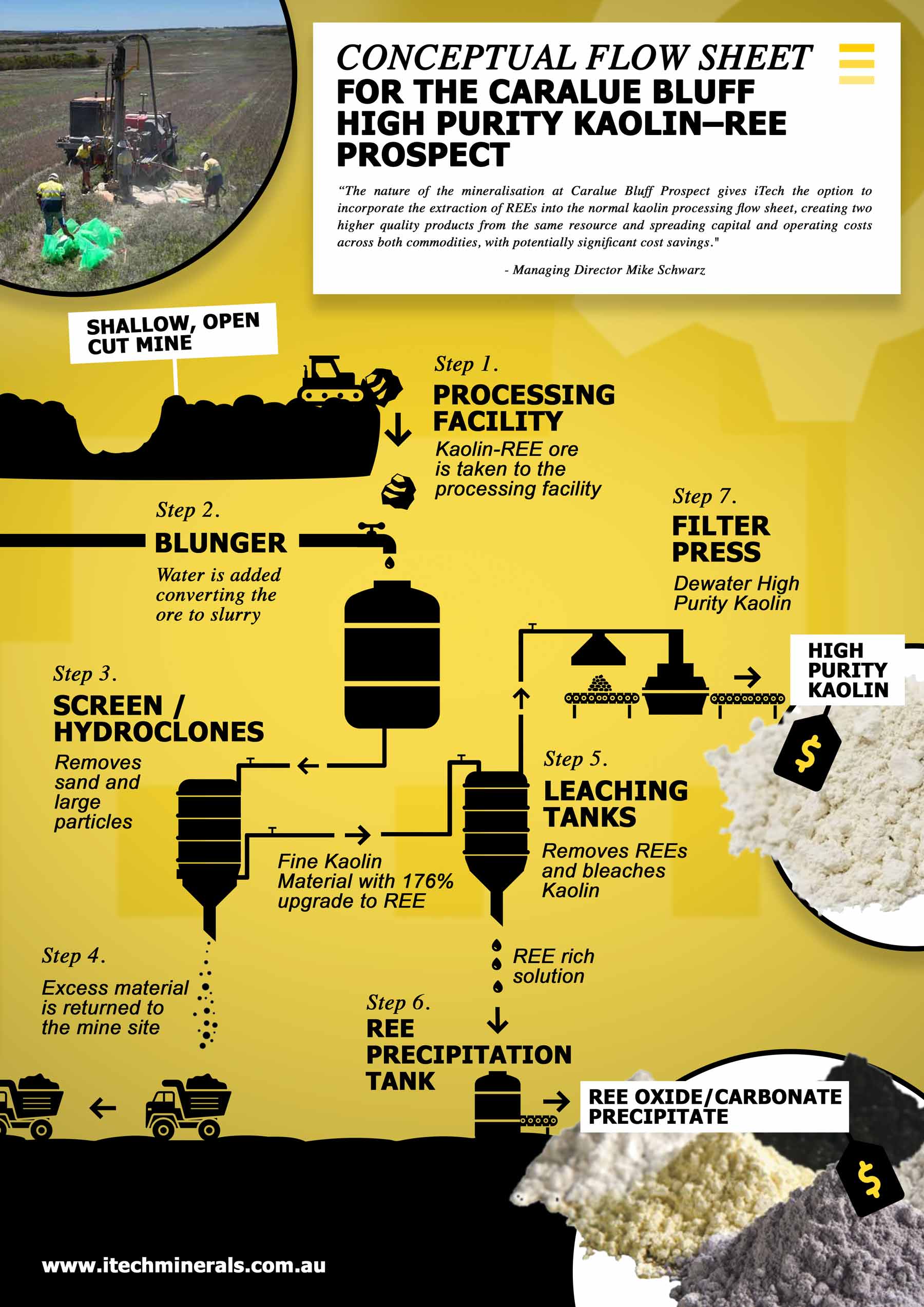

The Caralue Bluff Prospect was initially established as a high purity kaolin prospect with the identification of thick intervals of bright white kaolin, close to surface, in several historical drill holes. Having identified significant REEs in the kaolin rich intervals at Ethiopia, Burtons and Bartels Prospects, iTech geologists suspected that Caralue Bluff might also be prospective for regolith hosted REE mineralisation.

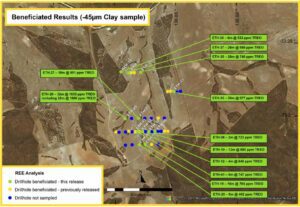

During the 2022 drilling program iTech tested a total area of 12 km x 12km by drilling of 260 holes. In the first batch of results from the drilling program intersected thick, high-grade clay hosted REE mineralisation, close to surface, over a large area of more than 10 km by 9 km, with intervals of up to 12m @ 2,343 ppm TREO from 9m.

In late 2022 iTech used this drilling data to release an Exploration Target of 110-220 Mt @ 635-832 ppm TREO and 19-22% Al2O3 for the Caralue Bluff REE-Kaolin Project. Importantly it remains open in multiple directions allowing for possible expansion in future drill programs.

A TIMELINE OF EXPLORATION

INFRASTRUCTURE

Like many industrial minerals, transportation, processing and marketing options for halloysite-kaolinite are as important as the raw product.

The Eyre Peninsula Kaolin Project is close to established transportation routes, facilities and shipping infrastructure. It is less than 30 kilometres from rail infrastructure and 70 kilometres from the industrial city of Whyalla. Whyalla is a potential location for the construction of a high purity alumina plant while port facilities at Lucky Bay provides an alternative option for direct shipping of ore or processed products.

Port facilities at Lucky Bay

A source of potable water for wet processing exists at the Campoona Graphite Project, with up to 80 megalitres per annum from the existing SA Water Jamieson Tank mains water system. Additional water requirements may be met with piped mains water, low salinity groundwater and, recycling and filtered processed water.

PARTNERSHIPS

The Company has assembled a highly skilled technical team through collaborations and partnerships with world renowned industry experts in the analysis, beneficiation and marketing of halloysite-kaolin material.

CSIRO

The Company is working with the CSIRO to develop a cost-effective method of quantitative halloysite analysis. In high grade kaolin, composed of a mixture of kaolinite and halloysite pseudomorphs, the halloysite component is often not detected by routine methods using X-ray diffraction in conjunction with formamide intercalation, particularly when dehydrated. To confirm the halloysite content of a sample, expensive and time-consuming scanning electron microscopy is required. This project will investigate refining current x-ray diffraction methods and a technique known as Fourier Transform Infrared Spectroscopy with Partial Least Square calibration to establish a rapid and cost-effective method of quantitative halloysite analysis.

METS ENGINEERING

The Company has also been working closely with METS Engineering to “crack the code” of developing a cost-efficient extraction method for the Rare Earths. This test work is being conducted on samples collected during the drilling program in 2022 and the early results have been highly encouraging with recoveries of up to 86% TREO achieved in leaching trials. The test work indicates a high chloride environment is required to liberate REEs from the clay host material and that the bulk of the REEs should be extractable and not bound within the lattice structure of the clay particles or in resistive minerals such as zircon or monazite. In the preliminary tests hydrochloric acid was used to create a high chloride environment but further test work will involve the substitution of common table salt to reduce acid costs. This has opened the path to creating a low cost and effective leaching process. While it is still early days, this has the potential to be an important breakthrough for the economics of the Caralue Bluff Prospect.

ANZAPLAN

Establishing offtake agreements is critical to the success of any industrial minerals project. Understanding the technical parameters of the customer’s requirements and beneficiating raw materials to customer specifications is vital to secure offtake agreements. The Company has partnered with ANZAPLAN, the leading consultancy and engineering company for industrial, specialty minerals and metals projects, to provide solutions across all phases of project development. Services provided by ANZAPLAN include process design, market requirements and applications, and high-end analytical services along the complete value chain from material analysis to project planning, plant engineering and, importantly, end user acceptance. ANZAPLAN offers a core competency in kaolin mining, processing and marketing with its sister company, Dorfner, one of the largest kaolin producers in Germany.